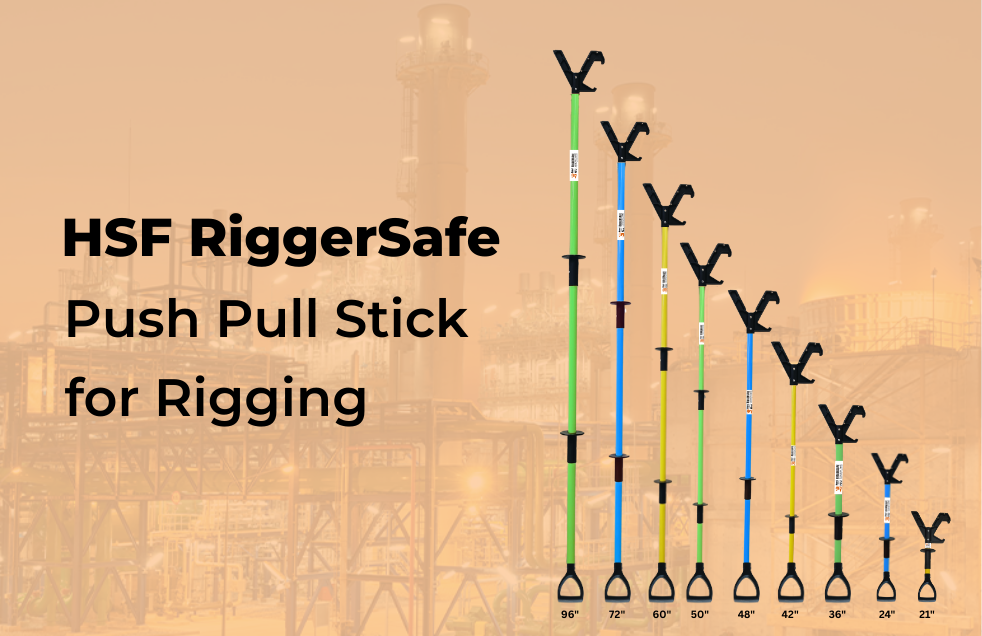

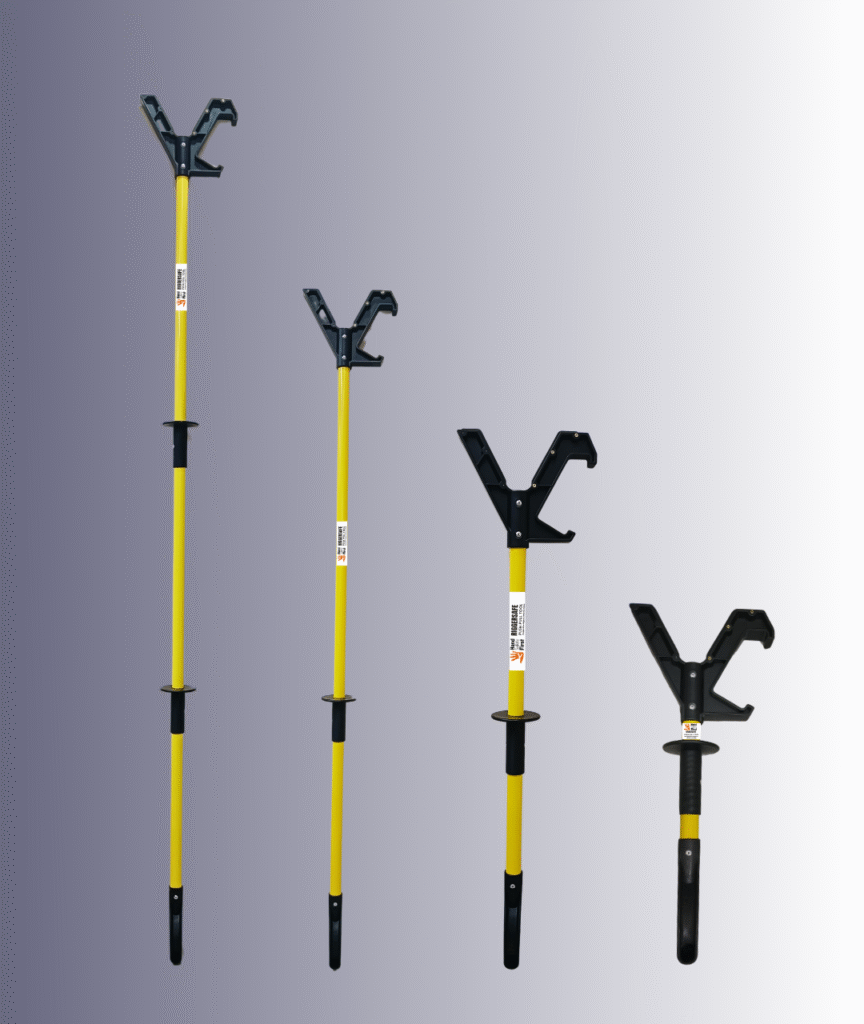

Launching Now The Widest Range Ever in Lengths and Colours –

HSF Riggersafe Push Pull Hand Safety Tool

HSF Riggersafe Push Pull Hand Safety Tool for Rigging — The Ultimate Hands-Free Safety Solution for Heavy Industries

Why Safe Rigging Matters More Than Ever :

In high-risk industrial environments such as oil rigs, construction sites, shipyards, steel plants, mining operations, and power generation facilities, safety is never optional. Every day, workers face hazards ranging from suspended loads swinging overhead to heavy equipment being maneuvered into tight, high-risk spaces. One wrong move can result in crushed hands, broken bones, or even fatalities.

That’s why the industry is shifting toward hands-free load control tools, and at the forefront of this movement are HSF Riggersafe Push Pull Hand Safety Tool For Rigging.

These tools are designed to keep workers out of danger zones while still maintaining precise control over heavy or awkward loads.

This blog takes a deep dive into:

- The fundamentals of rigging in heavy industries

- Why HSF Riggersafe Push Pull Hand Safety Tool For Rigging have become essential safety tools

- Their technical advantages and real-world applications

- How they help businesses meet safety compliance while improving productivity

Understanding Rigging in Heavy Industries

What is Rigging?

Rigging is the art and science of preparing, lifting, moving, and positioning heavy loads using mechanical lifting equipment like cranes, hoists, winches, and specialized rigging gear. It involves much more than simply attaching a hook to a load—it requires precise calculations, expert planning, and the right tools to ensure the lift is safe, efficient, and compliant with regulations.

In industries like oil & gas, shipbuilding, steel manufacturing, and construction, rigging operations are the backbone of material handling. From moving a multi-ton turbine into position to hoisting steel beams several stories high, each lift carries risks that must be managed through engineering control, proper training, and tools like HSF Riggersafe Push Pull Hand Safety Tool For Rigging.

Why Rigging is Critical to Heavy Industries

Rigging is not just a mechanical process—it is central to operational safety and efficiency. A single rigging failure can cause:

- Equipment damage worth millions

- Worker injuries or fatalities

- Extended project delays

- Legal and compliance issues

Industries that rely heavily on professional rigging include:

- Oil & Gas – Installing subsea pipelines, positioning blowout preventers (BOPs), and handling offshore modules

- Shipbuilding – Moving engines, propellers, and ship sections into place

- Steel & Manufacturing – Lifting large fabricated components, molds, and heavy assemblies

- Mining – Installing crushers, conveyors, and large processing equipment

- Construction – Hoisting and placing steel structures, concrete slabs, and pre-fabricated units

- Power & Energy – Rigging turbines, transformers, and high-voltage switchgear

In all these sectors, HSF Riggersafe Push Pull Hand Safety Tool For Rigging are increasingly used as a standard load-control safety tool to improve precision while keeping workers at a safe distance.

Core Principles of Safe Rigging

To ensure successful and safe rigging operations, every lift should follow these principles:

- Load Control – Keeping the load balanced and steady using tools like HSF Riggersafe Push Pull Hand Safety Tool For Rigging.

- Center of Gravity Awareness – Knowing where the weight is concentrated prevents tipping or dangerous swinging.

- Safe Lifting Path – Avoiding hazards in the load’s path, especially overhead structures and power lines.

- Tool Selection – Using the right rigging gear, including hands-free tools such as HSF Riggersafe Push Pull Hand Safety Tool For Rigging to avoid direct hand contact.

5. Rigging Inspections – Checking all slings, shackles, hooks, and push/pull tools for wear and damage before use.

Hands-Free Rigging — The New Safety Standard

Hands-free rigging has become a global best practice for industrial lifting. Traditional rigging often required workers to physically guide loads with their hands, placing them dangerously close to pinch points, crush zones, and swinging hazards.

With HSF Riggersafe Push Pull Hand Safety Tool For Rigging:

- Workers can guide and position suspended loads from a safe distance

- The risk of finger, hand, and arm injuries is drastically reduced

- Safety officers can ensure compliance with HSE (Health, Safety, and Environment) standards

- Workers can guide and position suspended loads from a safe distance

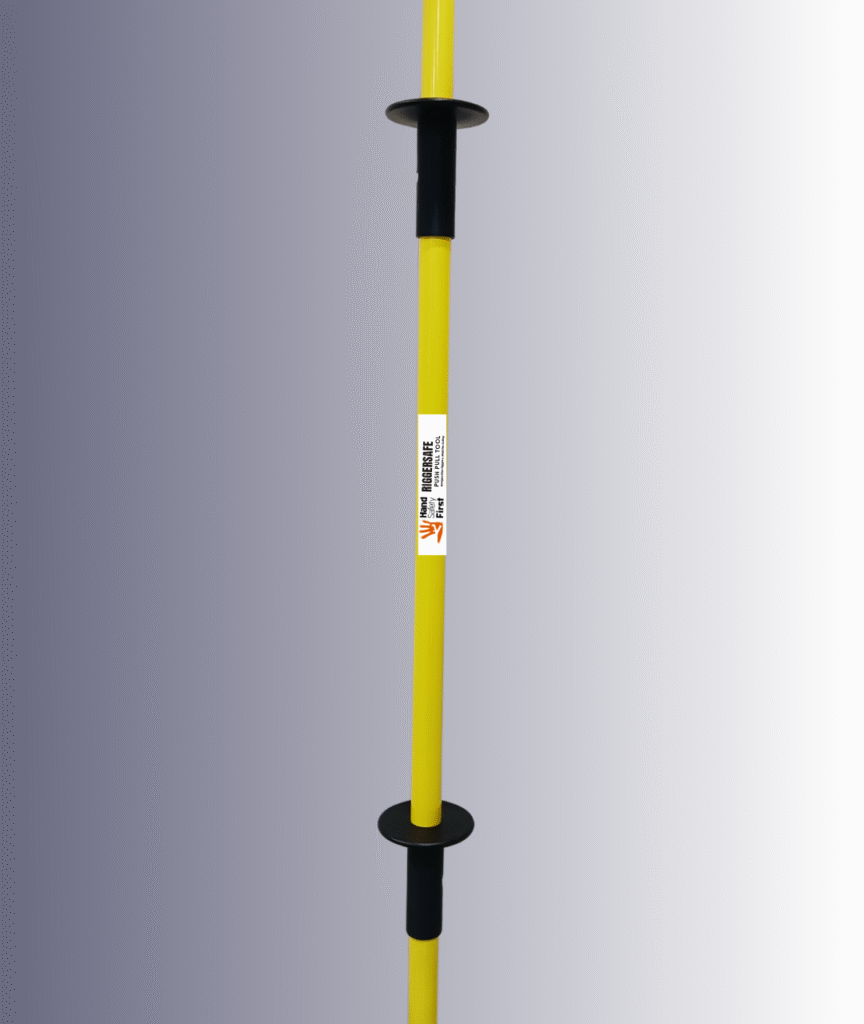

Technical Advantages of HSF Riggersafe Push Pull Hand Safety Tool For Rigging

Feature | Benefit |

Industrial-Grade Fiberglass Shaft | Non-conductive, corrosion-resistant, and strong enough for heavy-duty use |

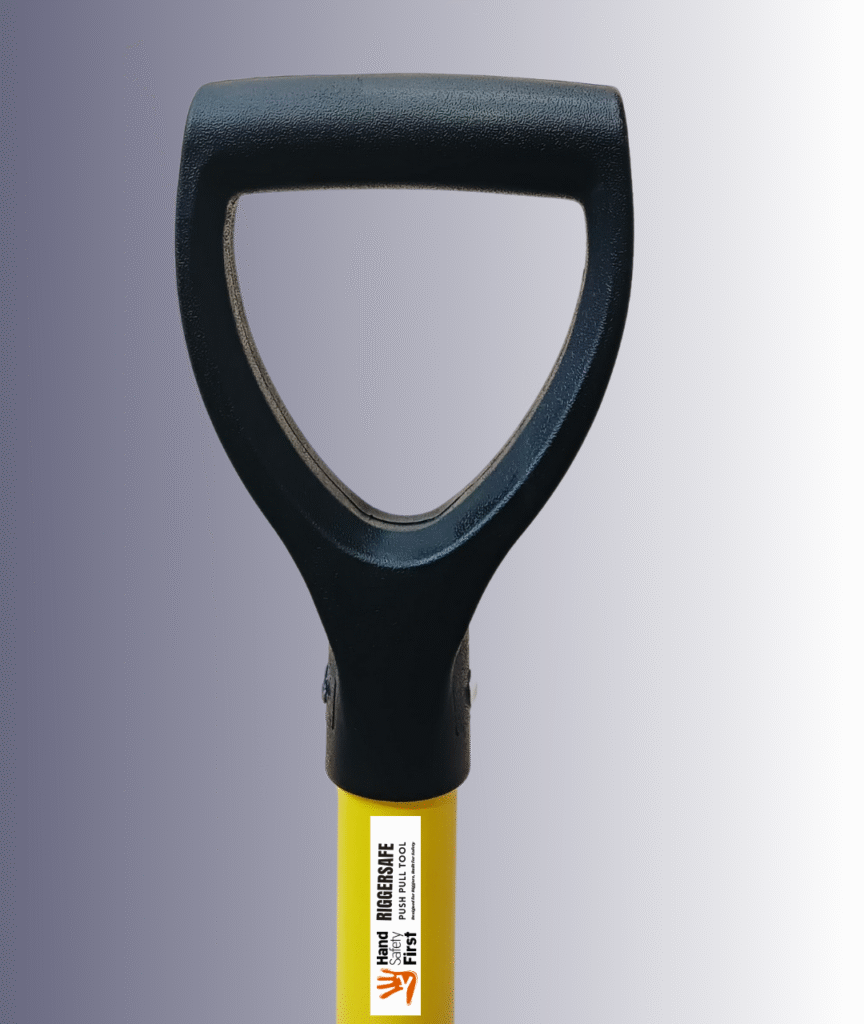

Ergonomic D-Handle | Comfortable grip, reduces operator fatigue during long shifts |

6-inch Wide-Face Push Head | Stable load contact, better control |

Integrated Safety Guard | Prevents hand slippage into danger zones |

High-Visibility Yellow Coating | Easy to spot on busy worksites |

Applications in Heavy Industries

Oil & Gas

- Guiding suspended pipelines into place

- Positioning heavy BOP units on offshore rigs

Construction

- Controlling steel beam placement during crane lifts

- Directing pre-cast concrete panels into tight spots

Shipbuilding & Offshore

- Aligning ship sections during assembly

- Managing load-outs of engines and propeller shafts

Manufacturing & Fabrication

- Moving CNC machines and heavy presses into position

- Handling large dies and molds safely

Power Generation

- Rigging heavy turbines for installation

- Guiding transformers into substations

In all these scenarios, HSF Riggersafe Push Pull Hand Safety Tool For Rigging make load control safer, faster, and more precise.

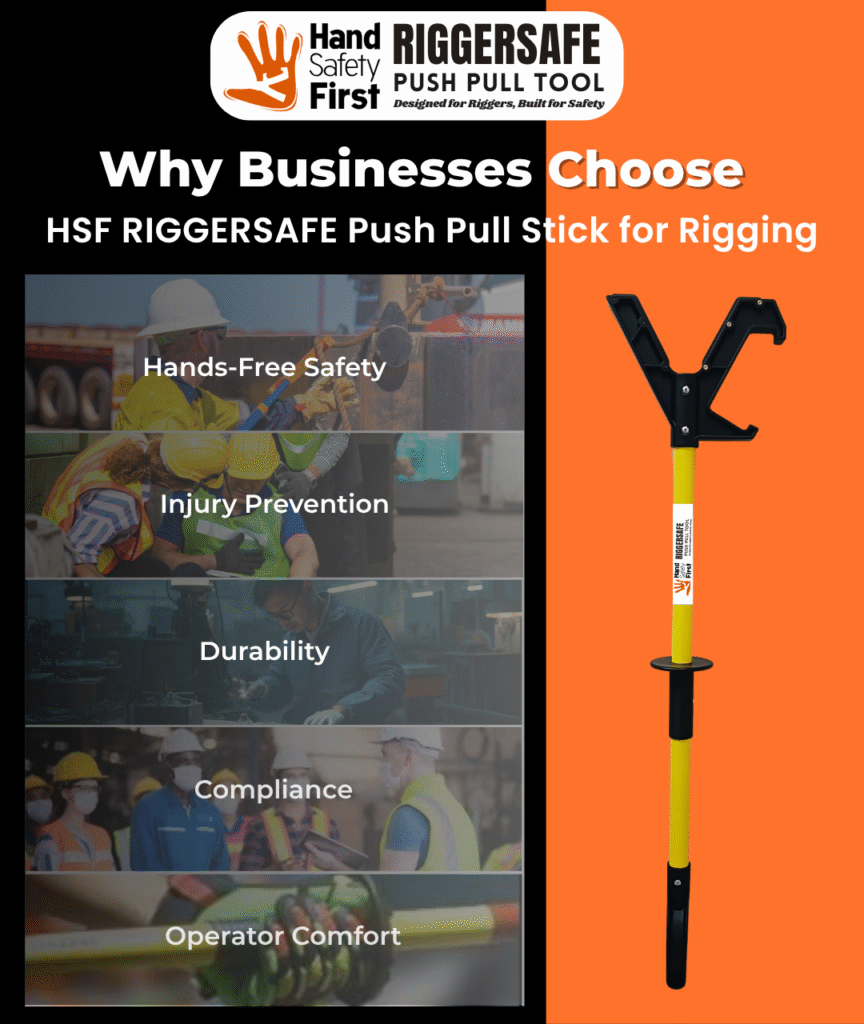

Why Businesses Choose HSF Riggersafe Push Pull Hand Safety Tool For Rigging

- Hands-Free Safety – Minimizes direct load contact

- Injury Prevention – Reduces crush and pinch hazards

- Durability – Performs in extreme temperatures (-40°C to +60°C)

- Compliance – Meets or exceeds safety regulations worldwide

- Operator Comfort – Ergonomic design lowers fatigue

How to Choose the Right HSF Riggersafe Push Pull Hand Safety Tool For Rigging

- Length – Choose from 21”, 42”, 50”, 72”, or 96” depending on the required reach.

- Push Head Size – Standard 6” rubberized head for maximum load stability.

- Insulation – Ensure non-conductive fiberglass for electrical safety.

- Handle Style – D-handle with safety guard for best grip and control.

Comparison with Traditional Tools

Feature | HSF Riggersafe Push Pull Hand Safety Tool For Rigging Stick | Traditional Rigging Tool |

Hands-Free Operation | ✅ Yes | ❌ No |

Electrical Insulation | ✅ Yes | ⚠ Rare |

Ergonomic Design | ✅ Yes | ⚠ Limited |

Built-in Safety Guard | ✅ Yes | ❌ No |

High Visibility | ✅ Yes | ⚠ Low |

Modern Rigging Innovations

Today’s heavy industries are adopting smarter, safer rigging technologies :

- Hands-Free Rigging Tools – Like HSF Riggersafe Push Pull Hand Safety Tool For Rigging and magnetic taglines

- Remote-Controlled Lifting Devices – Keeping workers away from danger zones

- Smart Load Monitoring Systems – Real-time data on load weight and movement

- Color-Coded Equipment – For quick visual inspections and error prevention

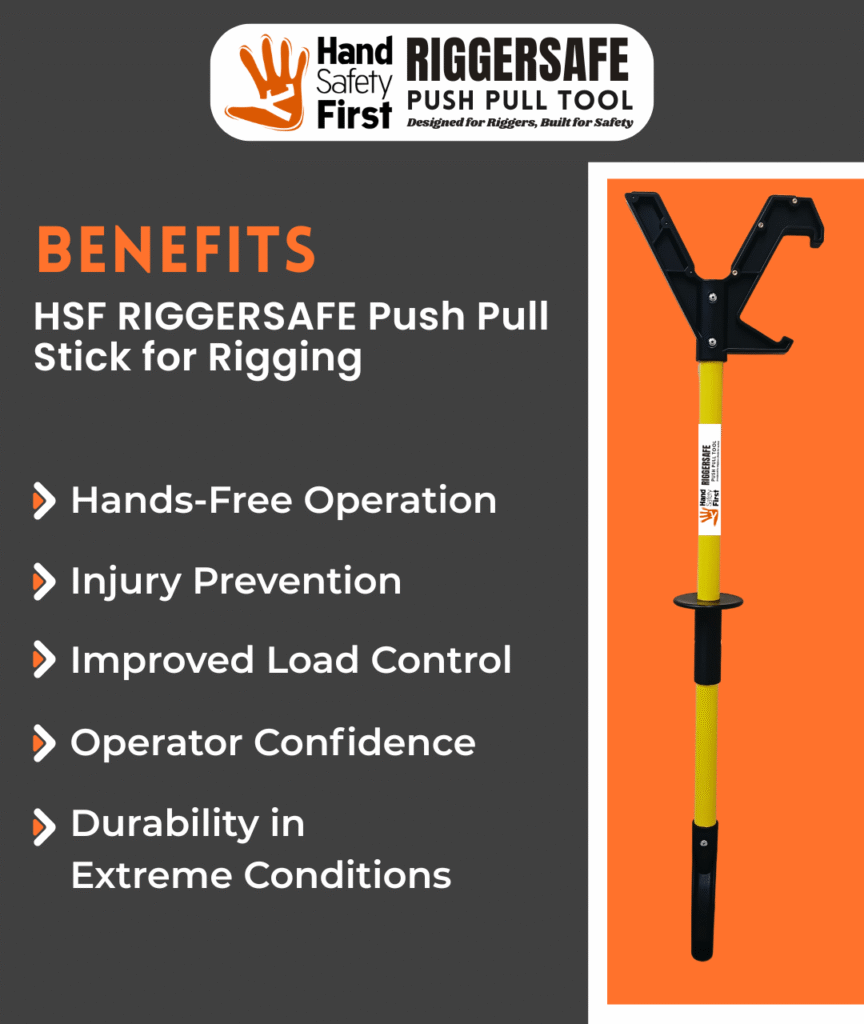

Visuals and Media — HSF Riggersafe Push Pull Hand Safety Tool For Rigging

Benefits of HSF Riggersafe Push Pull Hand Safety Tool For Rigging

Hands-Free Compliance

Stay aligned with modern rigging safety standards by removing hands from the load path.

Injury Prevention

Prevent pinch points, hand crush injuries, and electrical contact with insulated tools.

Improved Load Control

Wide-faced rubber heads stabilize movement, helping riggers execute precise placements.

Operator Confidence

Lightweight yet sturdy design helps riggers work with confidence and reduced fatigue.

Durability in Extreme Conditions

Resistant to chemicals, saltwater, and temperature fluctuations—ideal for rigging in harsh environments.

HSF Riggersafe Push Pull Hand Safety Tool

Precision Blue – HSF Riggersafe Push Pull Hand Safety Tool

The HSF Riggersafe Push Pull Hand Safety Tool in Precision Blue is designed for technicians who require pinpoint accuracy when aligning and controlling suspended or rolling loads. Blue offers high contrast in bright deck environments and against structural steel, allowing operators to maintain visual focus.

Use Case: Offshore drill floor alignment, precision positioning of valves and pipe joints.

Technical Benefit: Enhances operator accuracy during fine load adjustments, reducing misalignment errors.

Industries: Oil & Gas, Shipbuilding, Marine Cargo.

Safety Green – HSF Riggersafe Push Pull Hand Safety Tool

The HSF Riggersafe Push Pull Hand Safety Tool in Safety Green is ideal for plant environments, chemical facilities, and utility zones where green signals “safety” and high visibility is crucial. Green tools stand out in indoor and confined-space conditions.

Use Case: Plant maintenance, refinery equipment positioning, power utility handling.

Technical Benefit: Safety visibility in high-clutter industrial plants; reduces misplacement and tool confusion.

Industries: Petrochemical Plants, Utilities, Refineries.

Bright Yellow – HSF Riggersafe Push Pull Hand Safety Tool

The HSF Riggersafe Push Pull Hand Safety Tool in Bright Yellow is the flagship safety leader’s tool. Yellow is universally recognized as the highest visibility color, making it ideal for open yards, steel fabrication shops, and offshore decks.

Use Case: Crane lifts, module installations, heavy construction projects.

Technical Benefit: Maximum contrast visibility ensures supervisors and riggers maintain tool sightline at all times.

Industries: Offshore, Civil Construction, Steel Fabrication.

HSF Riggersafe Push Pull Hand Safety Tool Sizes – Detailed Technical Applications

21” HSF Riggersafe Push Pull Hand Safety Tool

Application: Confined-space rigging, subsea modules, maintenance inside vessels.

Technical Advantage: Ultra-compact, giving operators fingertip precision in areas where standard tools cannot be maneuvered.

24” HSF Riggersafe Push Pull Hand Safety Tool

Application: Mechanical rooms, utility vaults, small load adjustments.

Technical Advantage: Adds slight reach over the 21” model while maintaining compact form for technician-level control.

36” HSF Riggersafe Push Pull Hand Safety Tool

Application: Rig floor drill pipe guiding, steel fabrication yards, marine decks.

Technical Advantage: Provides balance between control and distance, suitable for medium load handling.

42” HSF Riggersafe Push Pull Hand Safety Tool

Application: Offshore cargo handling, crane-assisted pipe lifts.

Technical Advantage: Delivers additional leverage for maneuvering heavy suspended loads without close proximity.

48” HSF Riggersafe Push Pull Hand Safety Tool

Application: Structural construction, prefabricated component handling.

Technical Advantage: Provides extended distance for safer handling while retaining operational maneuverability.

50” HSF Riggersafe Push Pull Hand Safety Tool

Application: Pipeline yards, large valve positioning, onshore rigging.

Technical Advantage: Unique mid-size tool offering extended torque control for pipe bundle management.

60” HSF Riggersafe Push Pull Hand Safety Tool

Application: Offshore platforms, ship decks, large-scale rigging setups.

Technical Advantage: Longer safety distance while maintaining controlled handling in dynamic lifting zones.

72” HSF Riggersafe Push Pull Hand Safety Tool

Application: Cargo handling, offshore crane operations, marine load transfers.

Technical Advantage: Long reach provides maximum distance from heavy swinging loads, reducing operator risk.

96” HSF Riggersafe Push Pull Hand Safety Tool

Application: Extreme offshore environments, bulk cargo, and high-risk lifts.

Technical Advantage: Maximum operator clearance, ensuring hands never enter pinch zones during dangerous suspended load operations.

Conclusion

HSF Riggersafe Push Pull Hand Safety Tool for Rigging are more than just accessories—they are critical safety enablers that allow rigging teams to work more confidently and more productively. By reducing direct load contact, they protect workers from serious injuries while meeting the highest safety and compliance standards.

If you’re serious about reducing risks, preventing downtime, and ensuring safe lifting practices, HSF RIGGERSAFE Push Pull Sticks for Rigging belong in every rigging toolkit.

FAQ's – HSF Riggersafe Push Pull Hand Safety Tool for Rigging

Are they non-conductive?

Yes. Made with industrial-grade fiberglass for electrical safety.

Can they be used in harsh environments?

Yes. Operational range is -40°C to +60°C with full corrosion resistance.

What lengths are available?

21”, 42”, 50”, 72”, and 96”.

How do they prevent injuries?

They keep hands away from pinch points and crush zones during load handling.

Have An Enquiry For Us?

Fill The Form