HSF Riggersafe Push Pull Hand Safety Tool - Windy Rigging Operations

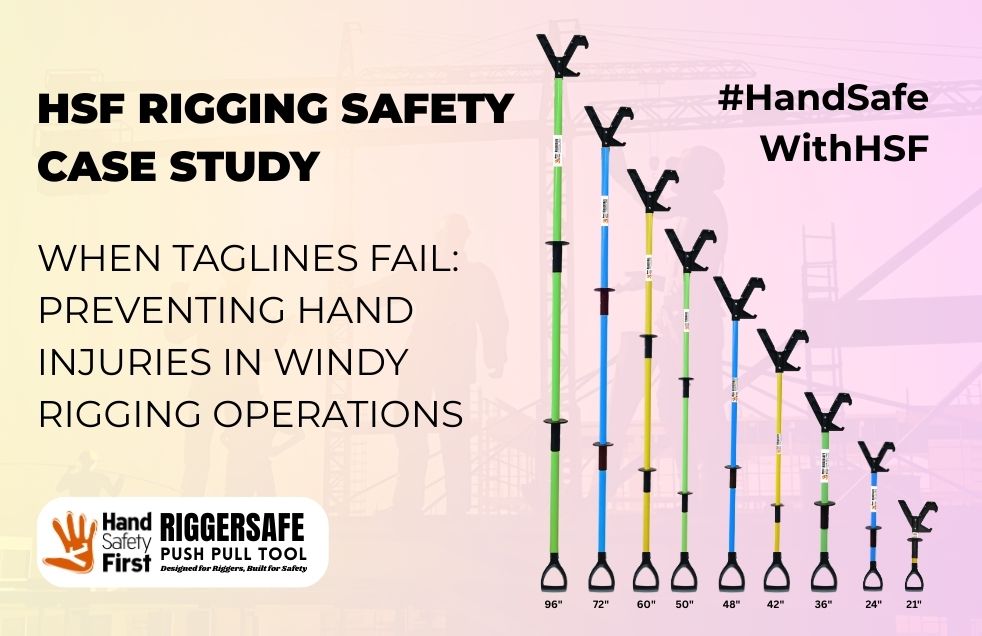

When Taglines Fail: How the HSF Riggersafe Push Pull Hand Safety Tool Prevented a Hand Injury During Windy Load Alignment

Background / Context

In oil & gas, marine, and construction lifting, rope taglines are widely used to control suspended loads and keep crews at a distance. They’re effective for long-range guiding and reducing swing — but they have limits:

Wind can suddenly overpower tagline control.

Close-in alignment (final 0.5–1.0 m before landing/fit-up) often demands precision, which taglines alone don’t provide.

In loss-of-control moments, riggers may instinctively reach for the load — putting hands in pinch/crush zones.

Why this matters: hand and finger injuries are among the most frequent recordable incidents in lifting operations, driving lost time, cost, and non-compliance.

Incident Scenario (Unsafe Practice)

Site conditions: structural steel lift; gusting wind; limited laydown space.

Control setup: one rope tagline; no close-control tool available.

Sequence of events (timeline):

Load picked and slewed toward set-down.

A gust pushes the load; tagline slips through the rigger’s gloved hand.

To arrest swing and “save” the landing, the rigger instinctively grabs the steel.

Contact with a sharp edge leads to a hand sprain and cut; operation paused; first aid administered.

Consequences / Impact

Injury: hand sprain + laceration (sutured).

Lost Time: 10 days (restricted duty + recovery).

Operational: schedule slip (crew short, re-brief, re-permit).

Cost drivers: medical, overtime/backfill, crane standby, re-inspection, paperwork.

Reputation: client KPI impact; corrective actions mandated.

One brief loss of control cascaded into avoidable downtime and cost.

Root Cause Analysis

Immediate cause: loss of tagline effectiveness in gusty wind → instinctive hands-on contact.

Underlying causes:

Control mismatch: tagline = distance control, not close-in alignment.

Tooling gap: no hands-free close-control device available at the set-down point.

Procedural gap: JSA didn’t define wind thresholds for adding a second control, or stop/pause criteria.

Human factors: time pressure; “save the lift” mindset; overreliance on one control (rope).

Training: insufficient emphasis on never substituting hands when control is lost.

Lesson Learned

Taglines guide from afar; they do not align up close.

When precision is needed (final positioning, dogging into place, navigating obstructions), crews require a rigid, hands-free interface that provides leverage without hand contact.

Establish wind/action thresholds: if gusts exceed X m/s or control degrades → add Push Pull Tool or pause.

HSF Solution (Safe Practice)

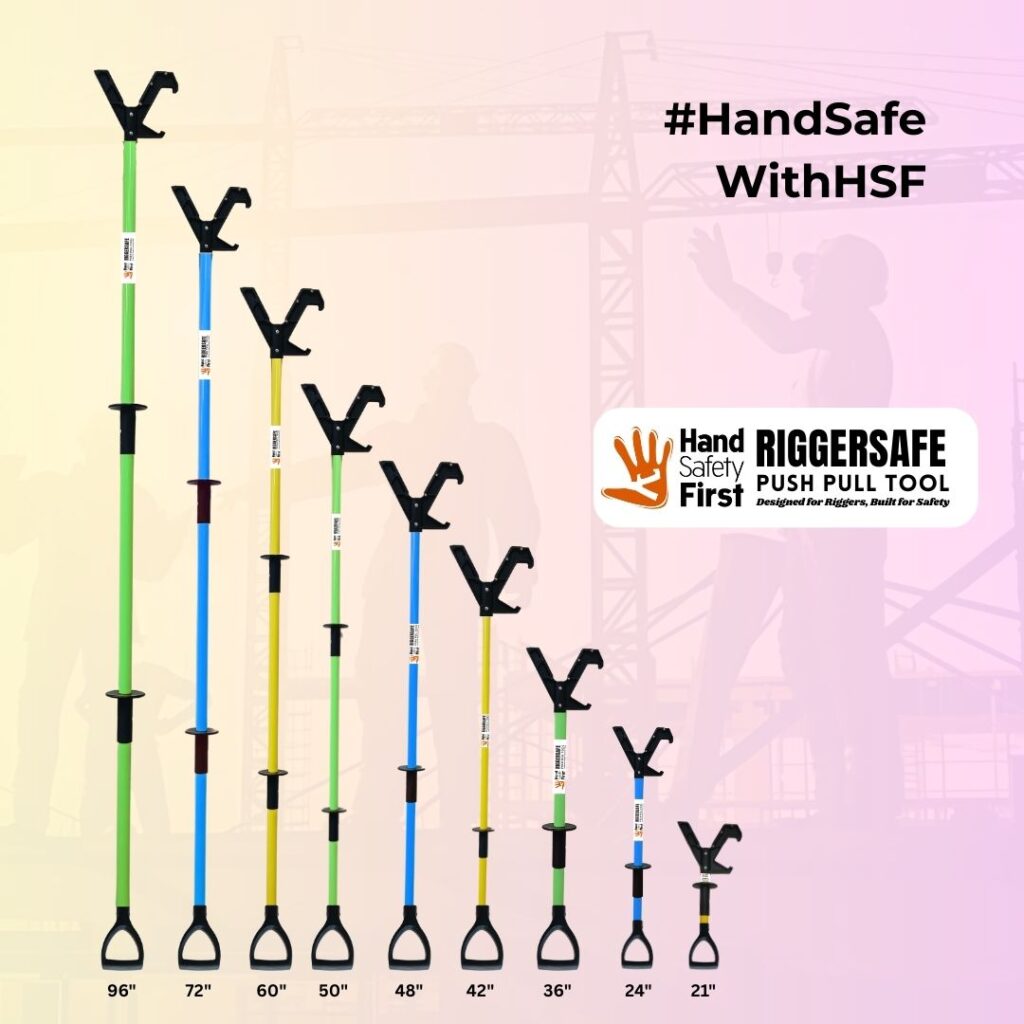

HSF Riggersafe Push Pull Hand Safety Tool closes the gap between rope and bare hands:

1.5 m safe distance keeps hands out of the line of fire.

Rigid control & leverage for close-in alignment (the last 0.5–1.0 m before landing).

Ergonomic grip and reinforced tip for positive contact on beams, frames, pipe spools, crates, and skids.

Predictable control in wind: unlike rope slip, a rigid stick resists sudden loss of tension.

Hands-free compliance: supports client and project hands-off policies.

How it integrates with taglines:

Use taglines for approach & swing control.

As the load enters the alignment zone, transition to one or two HSF Riggersafe Push Pull Hand Safety Tool for precise positioning and landing — no hands on load at any time.

Results (If Applied)

Across comparable lifts where HSF Riggersafe Push Pull Hand Safety Tool were introduced alongside taglines, sites reported:

Marked reduction in hand/finger contacts during load landing and fit-up.

Fewer pauses/re-sets in gusty conditions (more predictable final control).

Faster, cleaner landings with better crew confidence and communication.

Improved compliance posture during audits and client walk-downs.

(Pro tip: Track “hands near suspended load” observations before/after rollout to quantify improvement.)

Left (Rope only) | Right (HSF Stick) |

gust → rope slips → rigger reaches → hand at risk (sprain/cut). | gust → controlled push/pull from 1.5 m → smooth alignment → zero hand contact. |

Equip crews with the HSF Riggersafe Push Pull Hand Safety Tool to keep hands off loads — even when the wind picks up and precision matters.

#HandsSafeWithHSF

If you want to see how the HSF Riggersafe Push Pull Hand Safety Tool can improve your rigging operations,

Send us a Mail on info@handsafetyfirst.com

Visit us:

Website – riggersafe.com

Have An Enquiry For Us?

Fill The Form

Fill The Form