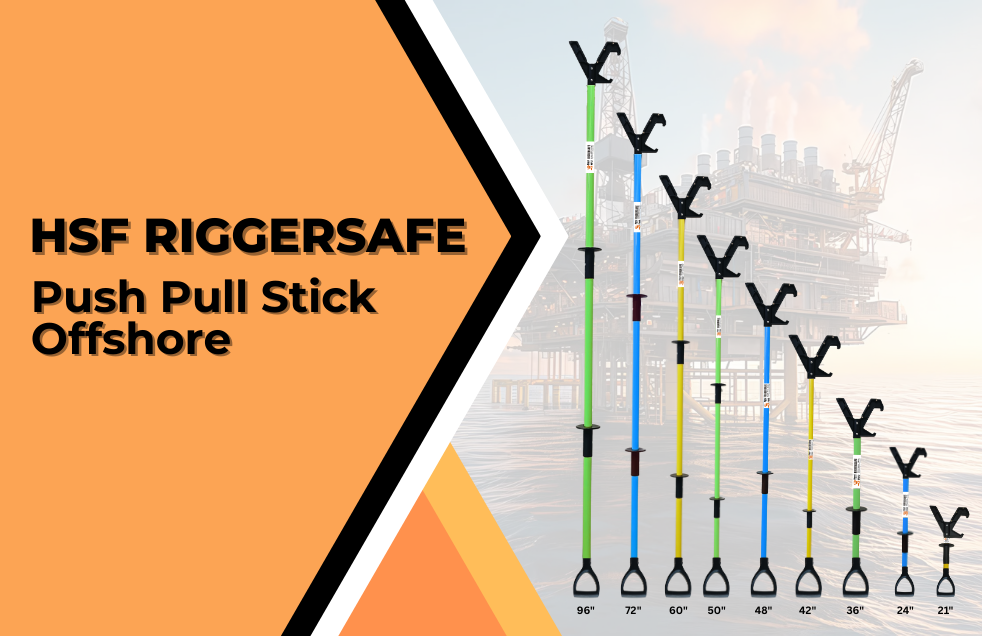

Launching Now The Widest Range Ever in Lengths and Colours – HSF RiggerSafe Push Pull Hand Safety Tool

HSF RiggerSafe Push Pull Hand Safety Tool – The Ultimate Safety Solution for Offshore Heavy Industries

Offshore Work Demands Offshore-Grade Safety

Offshore heavy industries — from oil & gas to renewable energy and marine construction — operate in some of the world’s harshest and most unpredictable environments. These sectors require precision, endurance, and, above all, safety. Whether it’s a crew member on a drilling platform, a technician installing wind turbines, or a rigger guiding a suspended load on a supply vessel, one wrong move can cause severe injury or costly delays.

That’s where the HSF RiggerSafe Push Pull Hand Safety Tool offshore becomes a game-changer. Designed for industrial-grade performance, this tool allows workers to control, guide, and position heavy or suspended loads without placing their hands in danger zones. It’s a critical safety measure for industries where space is tight, loads are heavy, and environmental conditions are unforgiving.

This blog explores:

- The nature of offshore heavy industry operations.

- The safety hazards unique to offshore rigging and load handling.

- How the HSF RIGGERSAFE push pull stick offshore addresses these hazards with advanced technical features.

- Practical offshore scenarios where the tool delivers maximum value.

Offshore Activities in Heavy Industries – Where the HSF RiggerSafe Push Pull Hand Safety Tool Offshore Proves Essential

Offshore operations are not simply land-based tasks moved to the sea — they come with increased complexity due to isolation, weather, and space limitations. These operations are critical to global energy, infrastructure, and trade, and include:

Oil & Gas

- Offshore Drilling: Setting up and maintaining drilling rigs where large pipe sections and equipment must be positioned accurately.

- Well Intervention: Conducting repairs or upgrades on subsea wells using heavy intervention tools.

- FPSO Operations: Managing floating production storage and offloading units, where cranes constantly transfer equipment and cargo.

Offshore Renewable Energy

- Wind Turbine Installation: Lifting and aligning blades, towers, and nacelles that weigh several tonnes, often in high winds.

- Subsea Cable Laying: Positioning delicate, high-voltage cables on the seafloor without damage.

- Offshore Substation Maintenance: Managing large electrical components in confined marine platforms.

Marine & Civil Construction

- Jetty and Bridge Construction: Handling precast concrete segments over water.

- Port Terminal Building: Positioning heavy gantry cranes and dock equipment with precision.

Shipping & Logistics

- STS Transfers: Managing ship-to-ship cargo movements where vessels may shift with the tide.

- Offshore Supply Runs: Delivering critical materials to rigs, requiring safe load control during crane transfers.

In all these sectors, the HSF RiggerSafe Push Pull Hand Safety Tool offers a safe, hands-free way to guide suspended or moving loads, keeping crew members out of crush zones while maintaining operational efficiency.

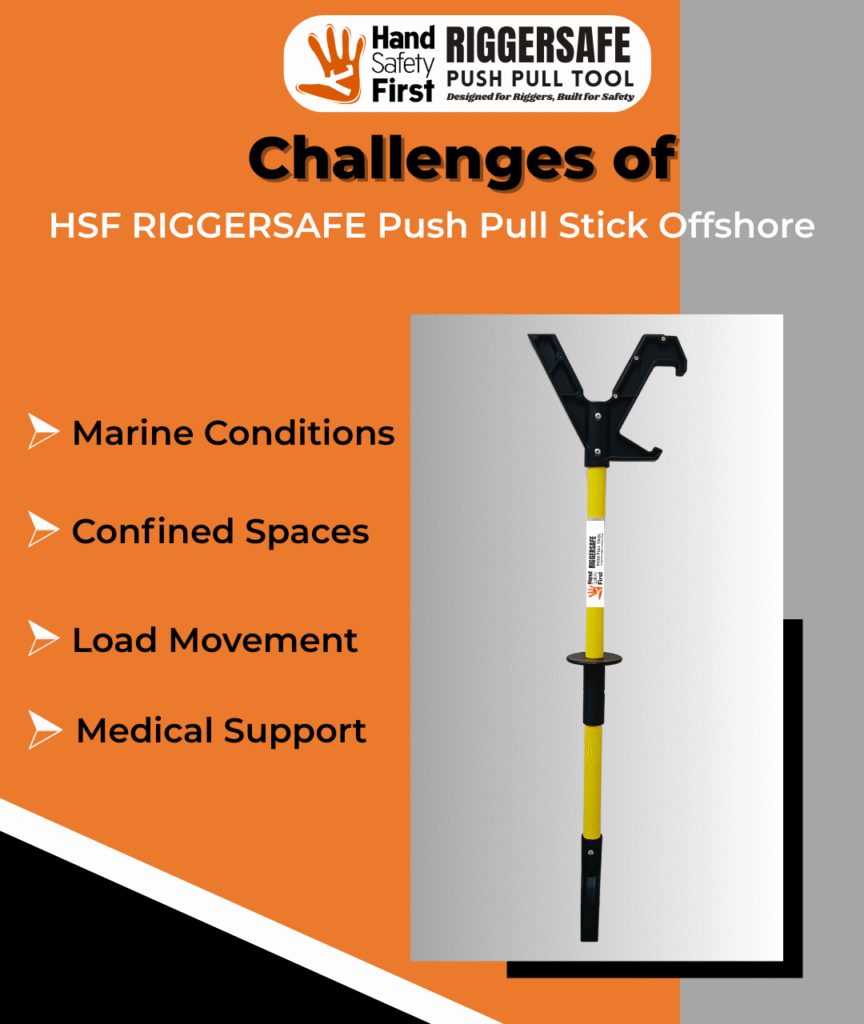

Challenges of Offshore Rigging – And Why the HSF RiggerSafe Push Pull Hand Safety Tool Offshore is Vital

Working offshore magnifies safety risks. Here’s why this tool is more than just “helpful” — it’s necessary.

Harsh Marine Conditions

Offshore work exposes equipment and personnel to salt spray, humidity, and extreme weather.

- HSF RiggerSafe Push Pull Hand Safety Tool offshore is built with industrial-grade fiberglass that resists corrosion and won’t conduct electricity — a must for marine safety.

Confined Workspaces and Elevated Platforms

Platforms and ships have limited maneuvering space, with narrow walkways and high drop-offs.

- The ergonomic D-handle and slim shaft of the HSF RiggerSafe Push Pull Hand Safety Tool offshore make it ideal for tight clearances while keeping hands at a safe distance.

Unpredictable Load Movement

Loads suspended from cranes can swing unexpectedly due to vessel motion or wind.

- The wide-face push head of the HSF RiggerSafe Push Pull Hand Safety Tool offshore ensures stability when redirecting or stopping load movement.

Remote Medical Support

Offshore sites are hours away from full medical facilities. Even minor injuries can escalate quickly.

- By reducing direct hand contact, the tool minimizes pinch, crush, and laceration risks — preventing injuries before they occur.

Technical Excellence of the HSF RiggerSafe Push Pull Hand Safety Tool Offshore

Feature | Offshore-Specific Advantage |

Industrial-Grade Fibreglass Shaft | Non-conductive, corrosion-resistant, perfect for wet, salty conditions. |

Ergonomic D-Handle with Integrated Safety Guard | Maintains grip in wet gloves; safety guard shields hands from impacts. |

Wide-Face Push Head with Rubberized Grip | Stabilizes swinging loads and prevents slipping. |

High-Visibility Safety Yellow Coating | Ensures visibility during night shifts or foggy conditions. |

Low-Maintenance Build | Wipes clean, withstands oil, salt, and chemicals. |

Multiple Length Options (21”–96”) | Suitable for different rigging tasks, from confined-space alignment to large crane operations. |

Operating Temperature Range -40°C to 60°C | Handles extreme Arctic and tropical offshore climates. |

Applications of the HSF RiggerSafe Push Pull Hand Safety Tool Offshore

- Suspended Load Guidance: Keep control over crane lifts during oil platform supply runs.

- Compliance with Hands-Free Policies: Meets offshore industry regulations for load handling safety.

- Confined Space Maneuvering: Adjust heavy gear inside narrow offshore maintenance rooms.

- Precision Equipment Placement: Align wind turbine blades in gusty offshore environments.

- Deck Cargo Positioning: Safely push or pull heavy cargo containers, pipe sections, or equipment across slippery offshore decks without direct hand contact.

- Hazard Zone Operations: Maintain safe distance when moving or repositioning tools and components near high-pressure lines, hot surfaces, or energized equipment.

Benefits of the HSF RiggerSafe Push Pull Hand Safety Tool Offshore

- Safety First: Eliminates the need for direct hand contact with dangerous loads.

- Enhanced Control: Stabilizes and guides loads precisely in high-risk conditions.

- Regulatory Compliance: Aligns with international offshore safety standards.

- Reduced Fatigue: Lightweight design ensures long shifts are more manageable.

- Durability: Engineered for years of use in saltwater, oil, and extreme weather.

Case Study – Offshore Oil Platform Supply Operation

During a North Sea oil platform supply operation, crane operators and deckhands used the HSF RiggerSafe Push Pull Hand Safety Tool offshore to guide containers from the supply vessel to the rig.

Before: Deckhands manually grabbed taglines, risking hand crush injuries when containers shifted unexpectedly in rough seas.

After: Using the push pull stick, workers guided loads with full control from a safe distance, resulting in zero hand injuries and faster load positioning — improving overall operational efficiency by 20%.

FAQs : HSF RiggerSafe Push Pull Hand Safety Tool Offshore

What is the HSF RiggerSafe Push Pull Hand Safety Tool offshore used for?

The HSF RiggerSafe Push Pull Hand Safety Tool offshore is designed for safe, hands-free load handling in offshore heavy industries. It allows workers to guide, control, and position heavy or suspended loads without direct hand contact, reducing the risk of crush and pinch injuries.

Why is the HSF RiggerSafe Push Pull Hand Safety Tool offshore important in offshore heavy industries?

Offshore environments are high-risk due to limited space, swinging loads, and harsh weather conditions. The HSF RiggerSafe Push Pull Hand Safety Tool offshore ensures workers maintain safe distances from hazardous loads, improving both safety and operational efficiency.

Is the HSF RiggerSafe Push Pull Hand Safety Tool offshore corrosion-resistant?

Yes. The tool’s industrial-grade fiberglass shaft is non-conductive and resistant to corrosion, making it ideal for saltwater and humid offshore conditions.

What are the typical offshore applications for the HSF RiggerSafe Push Pull Hand Safety Tool offshore?

Common applications include:

- Guiding suspended loads during crane lifts on oil platforms.

- Positioning wind turbine components offshore.

- Maneuvering heavy cargo during ship-to-ship transfers.

- Aligning subsea equipment in marine construction projects.

What length options are available for the HSF RiggerSafe Push Pull Hand Safety Tool offshore?

The HSF RiggerSafe Push Pull Hand Safety Tool offshore comes in lengths from 21” to 96”, making it suitable for both confined-space rigging and large-scale offshore lifting operations.

Does the HSF RiggerSafe Push Pull Hand Safety Tool offshore meet offshore safety regulations?

Yes. It supports compliance with “hands-free” lifting policies and international offshore safety standards, making it an approved tool for safety audits.

How does the HSF RiggerSafe Push Pull Hand Safety Tool offshore improve operational efficiency?

By allowing precise control of heavy or swinging loads, the tool reduces time spent on positioning and minimizes the need for rework due to load misalignment, boosting productivity in offshore operations.

HSF RiggerSafe Push Pull Hand Safety Tool Colors – Technical Purpose

Precision Blue – HSF RiggerSafe Push Pull Hand Safety Tool

The HSF RiggerSafe Push Pull Hand Safety Tool in Precision Blue is designed for technicians who require pinpoint accuracy when aligning and controlling suspended or rolling loads. Blue offers high contrast in bright deck environments and against structural steel, allowing operators to maintain visual focus.

Use Case: Offshore drill floor alignment, precision positioning of valves and pipe joints.

Technical Benefit: Enhances operator accuracy during fine load adjustments, reducing misalignment errors.

Industries: Oil & Gas, Shipbuilding, Marine Cargo.

HSF RiggerSafe Push Pull Hand Safety Tool

The HSF RiggerSafe Push Pull Hand Safety Tool in Safety Green is ideal for plant environments, chemical facilities, and utility zones where green signals “safety” and high visibility is crucial. Green tools stand out in indoor and confined-space conditions.

Use Case: Plant maintenance, refinery equipment positioning, power utility handling.

Technical Benefit: Safety visibility in high-clutter industrial plants; reduces misplacement and tool confusion.

Industries: Petrochemical Plants, Utilities, Refineries.

Bright Yellow – HSF RiggerSafe Push Pull Hand Safety Tool

The HSF RiggerSafe Push Pull Hand Safety Tool in Bright Yellow is the flagship safety leader’s tool. Yellow is universally recognized as the highest visibility color, making it ideal for open yards, steel fabrication shops, and offshore decks.

Use Case: Crane lifts, module installations, heavy construction projects.

Technical Benefit: Maximum contrast visibility ensures supervisors and riggers maintain tool sightline at all times.

Industries: Offshore, Civil Construction, Steel Fabrication.

HSF RiggerSafe Push Pull Hand Safety ToolSizes – Detailed Technical Applications

21” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Confined-space rigging, subsea modules, maintenance inside vessels.

Technical Advantage: Ultra-compact, giving operators fingertip precision in areas where standard tools cannot be maneuvered.

24” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Mechanical rooms, utility vaults, small load adjustments.

Technical Advantage: Adds slight reach over the 21” model while maintaining compact form for technician-level control.

36” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Rig floor drill pipe guiding, steel fabrication yards, marine decks.

Technical Advantage: Provides balance between control and distance, suitable for medium load handling.

42” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Offshore cargo handling, crane-assisted pipe lifts.

Technical Advantage: Delivers additional leverage for maneuvering heavy suspended loads without close proximity.

48” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Structural construction, prefabricated component handling.

Technical Advantage: Provides extended distance for safer handling while retaining operational maneuverability.

50” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Pipeline yards, large valve positioning, onshore rigging.

Technical Advantage: Unique mid-size tool offering extended torque control for pipe bundle management.

60” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Offshore platforms, ship decks, large-scale rigging setups.

Technical Advantage: Longer safety distance while maintaining controlled handling in dynamic lifting zones.

72” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Cargo handling, offshore crane operations, marine load transfers.

Technical Advantage: Long reach provides maximum distance from heavy swinging loads, reducing operator risk.

96” HSF RiggerSafe Push Pull Hand Safety Tool

Application: Extreme offshore environments, bulk cargo, and high-risk lifts.

Technical Advantage: Maximum operator clearance, ensuring hands never enter pinch zones during dangerous suspended load operations.

Conclusion – Safety Offshore is Non-Negotiable

Offshore heavy industry work is unforgiving. Precision and safety are not just desirable — they are survival essentials. The HSF RiggerSafe Push Pull Hand Safety Tool offshore is a proven tool that reduces risks, improves efficiency, and ensures compliance with industry safety protocols.

RiggerSafe – Because safe hands don’t touch the load.

Have An Enquiry For Us?

Fill The Form