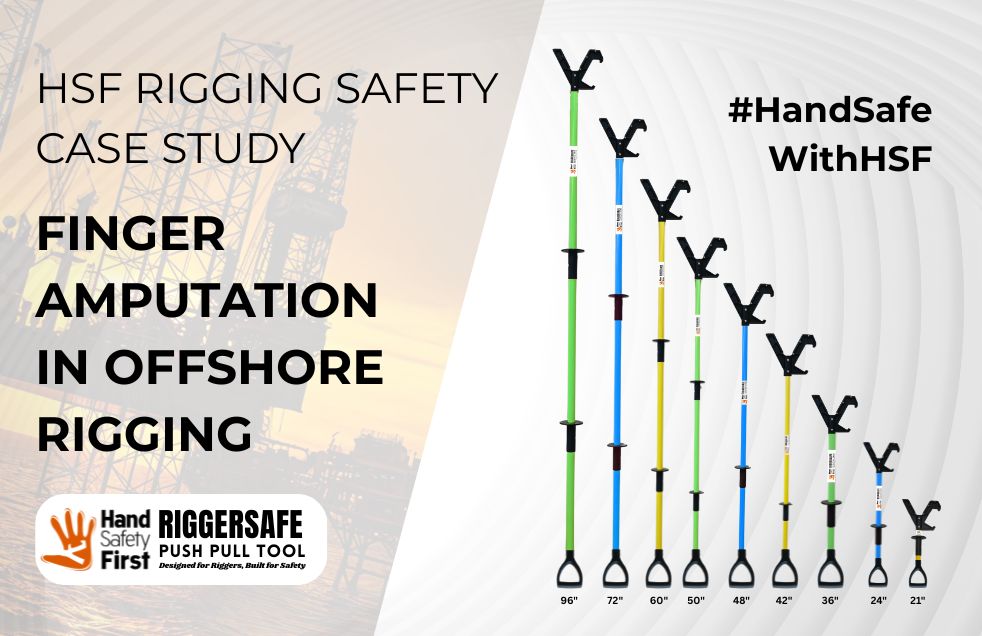

HSF Riggersafe Push Pull Hand Safety Tool - Finger Amputation in Offshore Rigging

“One Second Offshore: How the HSF Riggersafe Push Pull Hand Safety Tool Prevents Finger Amputation Risks”

Background / Context

Offshore lifting operations are some of the most challenging in the world. Unlike land-based construction, crews offshore must deal with:

Swell and vessel movement that cause suspended loads to shift unpredictably.

Strong winds that reduce control from traditional taglines.

Tight deck space, leaving little margin for error.

Despite safety campaigns, offshore workers often instinctively use their hands to guide or align loads during final positioning. This instinct puts hands in direct contact with rigging hardware, shackles, and pinch zones — the most dangerous places during a lift.

Industry data consistently shows hand and finger injuries as one of the top 3 recordable incidents in offshore rigging.

Incident Scenario (Unsafe Practice)

A common situation:

A suspended load is being landed onto the deck of an offshore platform.

The crew uses a rope tagline for initial swing control.

As the load nears final position, it begins to sway with the swell.

A worker instinctively reaches out with his hand to pull the load into alignment.

His fingers get caught in the gap of a shackle.

The result: partial finger amputation.

Consequences / Impact

Medical: Permanent partial finger amputation → lifelong disability.

Lost time: Worker removed from duty, recovery period, medical evacuation.

Operational delays: Permit to work suspended, investigation, crew re-brief.

Cost drivers:

Medical evacuation & treatment offshore.

Lost manhours and backfill costs.

Crane/vessel standby charges.

Penalties for missed KPIs.

Reputation: Client audit, corrective actions mandated, safety image impacted.

One instinctive action cascaded into major downtime, cost, and human impact.

Root Cause Analysis

Immediate cause: Fingers placed inside rigging hardware zone.

Underlying causes:

No hands-free alignment tool available during final positioning.

Dynamic offshore conditions (swell + wind) increased load movement.

Over-reliance on rope tagline — effective at distance but not close-in.

Human factor: instinct to grab & “save the lift.”

Gaps in training & procedure: not reinforcing “never hands on load.”

Lesson Learned

Offshore = high movement = high hand risk.

Taglines are good for distance control, but they cannot provide rigid, close-in alignment.

Workers must never substitute hands when control is lost.

To eliminate pinch-zone injuries, crews need a rigid, hands-free control tool.

HSF Solution (Safe Practice)

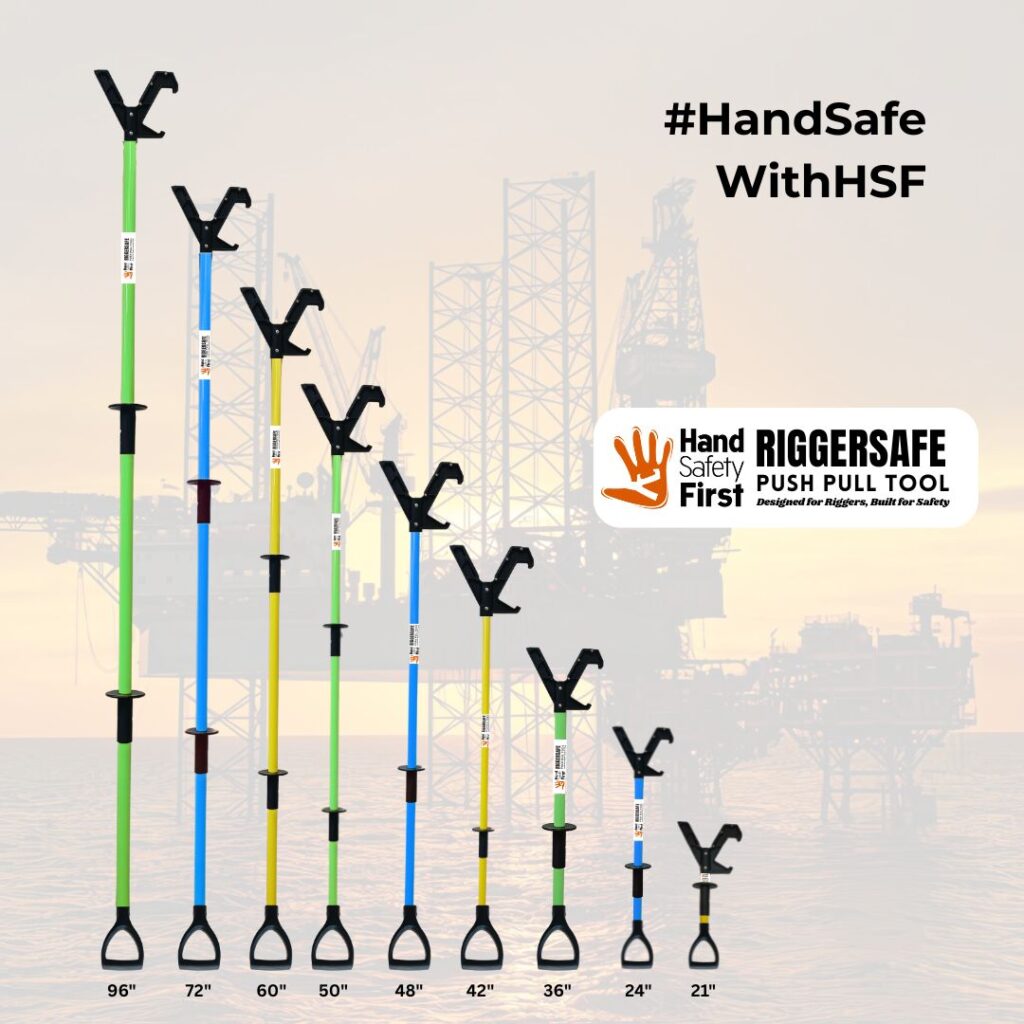

The HSF Riggersafe Push Pull Hand Safety Tool directly addresses this risk:

- Keeps hands 1.5 m away from suspended loads.

- Provides rigid leverage for precise final alignment — even in swell or wind.

- Prevents contact with shackles, slings, and load edges.

- Ergonomic grip & reinforced tip = reliable push/pull without slipping.

- Fully compliant with offshore Hands-Off Load policies.

How it works offshore:

- Use taglines for approach & swing control.

- As the load enters final alignment zone, switch to Push Pull Sticks.

- Crew achieves precise positioning — without a single hand touching the load.

Results (If Applied)

Offshore sites that rolled out HSF Riggersafe Push Pull Hand Safety Tool alongside taglines reported:

- Zero hand/finger contact during final positioning.

- Fewer delays caused by uncontrolled load movement.

- Improved crew confidence — safer and smoother landings.

- Positive compliance results during client audits.

Left (Unsafe) | Right (Safe) |

Worker reaching to grab load → fingers trapped in shackle (simple silhouette, no gore). | Worker using Push Pull Tool → load aligned smoothly, hands away from pinch zone. |

“One second of instinct. A lifetime of injury.”

“HSF Push Pull Stick = safer alignment offshore.”

- Don’t risk your crew’s hands offshore.

- Equip them with the HSF Riggersafe Push Pull Hand Safety Tool.

If you want to see how the HSF Riggersafe Push Pull Hand Safety Tool can improve your rigging operations,

Send us a Mail on info@handsafetyfirst.com

Visit us:

Website – riggersafe.com

Have An Enquiry For Us?

Fill The Form

Fill The Form